When it comes to data center construction, precision isn’t optional; it’s essential. The project doesn't only need to function at a high level; it needs to be a showcase for users of the data center to tour and experience. From the clean lines of perfectly aligned conduit bends and couplings to seamless coordination across trades, every detail matters. On a recent data center project, our Building Information Modeling (BIM) team played a pivotal role in ensuring that level of excellence was achieved.

BIM at Work

Our BIM team was instrumental throughout the project lifecycle. With over 40 equipment rooms and four major building sectors, each with unique layouts and space requirements, our team was tasked with creating a model that could adapt to change while maintaining schedule and quality.

Midway through the project, a major shift occurred: one of the building sector clients changed, resulting in a quick re-evaluation and re-design of the power and server rack requirements. Thanks to BIM, we were able to pivot without disrupting the overall schedule or workflow. The model allowed us to visualize and implement changes efficiently, keeping our field team on the very tight project schedule.

Between coordination and installation, we also utilized laser scanning to capture a true picture of each area once the gear was set. This allowed us to quickly adjust for field conditions while still maintaining the level of quality and precision our customer required.

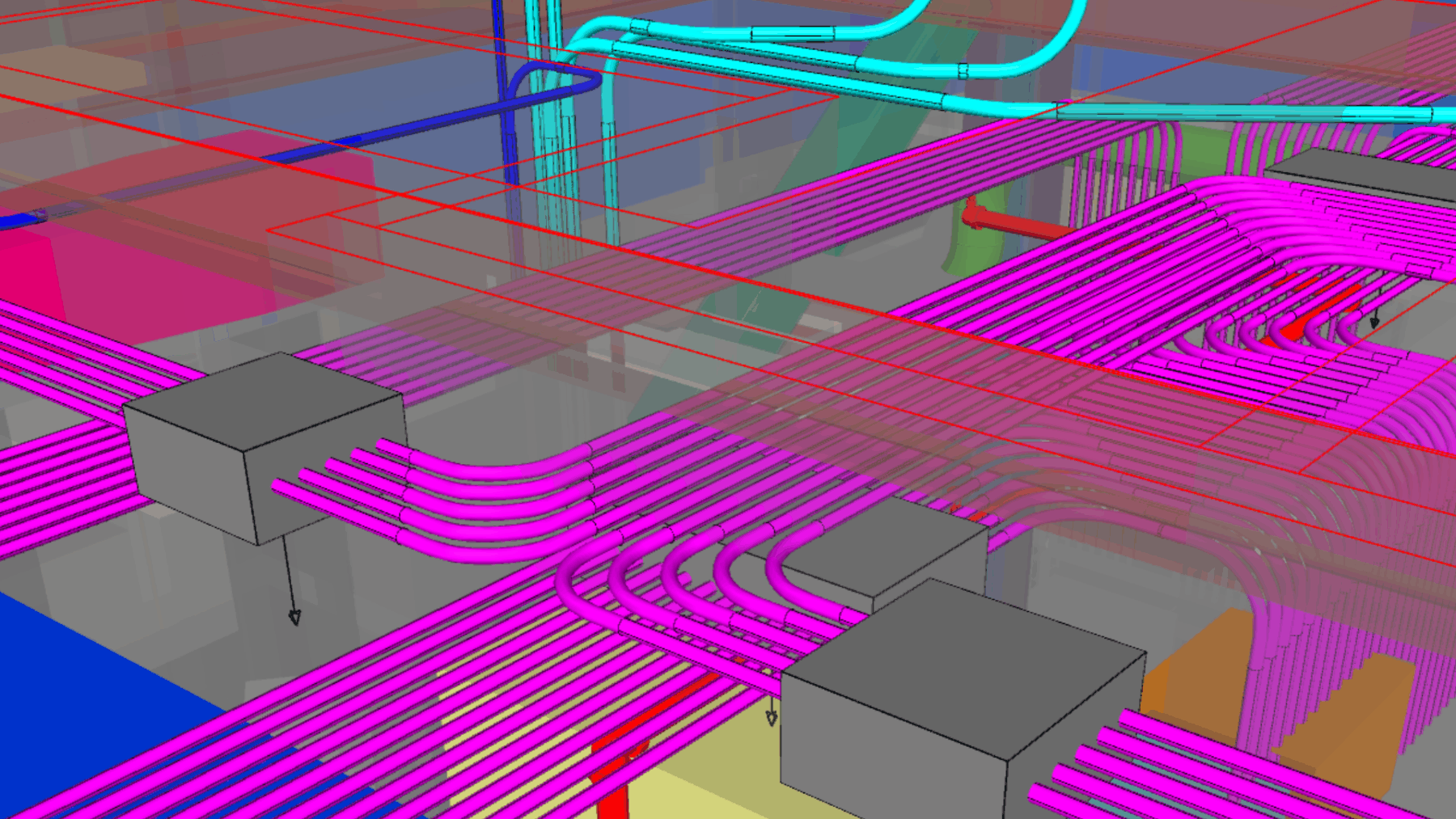

Data centers are inherently complex, with massive amounts of conduit and content that must be run by hand to align precisely with gear and infrastructure. To support the field teams, we used BIM coordination to integrate architectural, structural, and MEP trades into a unified model. This enabled us to identify potential clashes early and incorporate feedback from the project team during preplanning. The result; a model that wasn’t just theoretical, but practical, and was used every day in the field and during prefabrication.

Prefab on the Project

In our off-site prefab shop, our prefabrication team used the coordinated model to produce conduit bends that matched the drawings exactly. This allowed us to streamline production, reduce rework, and deliver higher-quality components. Each room received a conduit map with numbered bends that matched how they were loaded onto the truck, ensuring a smooth installation process.

By John Stelma

Senior BIM Coordinator Lead

Share this Blog Post

Leave a question or comment: