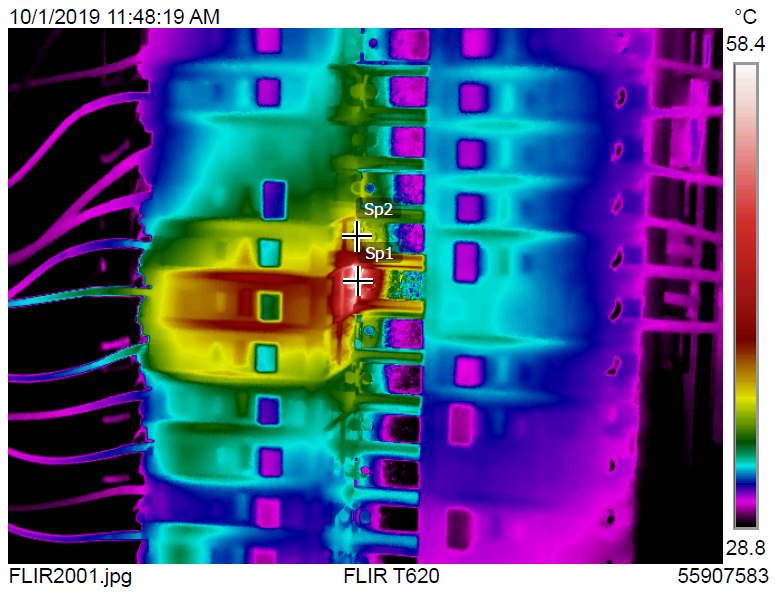

What is an IR Thermography Report?

An IR Thermography report is a study that is completed by a qualified specialist that uses a thermal imager to detect infrared energy (radiation/heat) coming from a piece of equipment. The energy is then converted to temperature and the distribution is displayed on an image. A report is then assembled that outlines the equipment's electrical overloads, failures, and hazards as well as hot spots and poor connections. The report also determines what troubleshooting, predictive maintenance, and condition monitoring actions are needed.

The primary goal of an IR Thermography Report is to confirm that the piece of equipment is running normally and that any abnormal heat patterns are detected. The abnormalities often indicate that defects or inefficiencies persist and must be mitigated.

Infrared Thermography is used in the following applications:

- To monitor electrical and mechanical equipment conditions

- To inspect bearing friction

- To monitor refractory insulation

- To locate gas, sludge, and liquid levels

Schedule an IR Scan Today.

Have any questions about IR Thermography Reports, or ready to schedule one? We're on it.

Why complete an IR Report?

An IR Thermography report will:

- Identify equipment abnormalities and issues

- Identify planned maintenance priorities

- Identify real time output

- Help you avoid expensive repairs and emergencies

- Increase your equipment's safety and insurability

- Reduce liability exposure

- Improve equipment performance and lifespan

- Provide you with tangible data on your equipment

- Not interfere with production and requires no direct contact with components or machines

Benefits of IR Studies

Prevents injuries

Increased equipment uptime, performance, and efficiency

Reduces unscheduled outages

Lowers overall maintenance costs

Provides peace of mind

Extends equipment lifespan

When to get an IR Thermography Report

It is recommended that an IR Thermography report is conducted on an annual basis to ensure that your equipment is operating as it should be. We also recommend that you check with your insurance company to see if an IR Thermography Scan is required within a specific time frame to keep coverage.

Additionally, IR Thermography Scans are often used after new equipment is installed to provide a baseline for future comparisons.

How much does an IR Scan cost?

Like many other reports or studies, there is no umbrella cost for an IR Thermography Report. On average we see most IR Thermography Reports costing between $2,000 and $5,000. The following factors affect the cost of a report:

- The amount of equipment that you want scanned. The larger the scope of equipment, the larger the cost.

- How long it takes to scan the equipment. Site accessibility, size, and environment all effect how long it takes to gather data on the equipment, effecting the cost.