Preventative maintenance—regardless of size or complexity—helps ensure that your facility is safeguarded against costly failures and aging equipment that puts your productivity at risk.

And we’re here to help.

Your success and productivity hinges on the health of your equipment. Unfortunately, equipment is often overlooked unless an issue or downtime occurs—which in many cases can be too late. By taking proactive measures to inspect, repair, upgrade, and support your equipment, we’ll help ensure that it’s safely and securely running at 100% capacity. Armed with experience and a deep understanding of your plant floor, we’re ready to get your facility in optimal condition.

Why Preventative Maintenance Matters

The average cost per hour of equipment downtime is $260,000

Aging equipment is the leading cause of unplanned downtime incidents

Unplanned downtime costs industrial manufacturers an estimated $50 billion annually

Our Preventative Maintenance Services

- General equipment upgrades

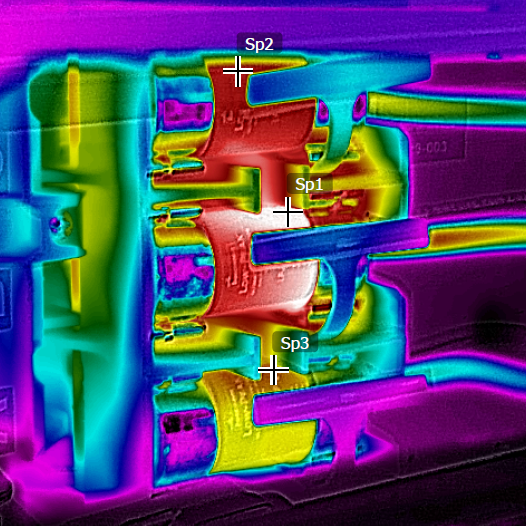

- Thermal imaging

- Power usage testing and diagnostic

- Switchgear cleaning and maintenance

- Transformer oil testing

- Relocating equipment

- Review individual circuits, wire sizes, and fuses

- Power distribution inspection

- Grounding testing

- Equipment power drops

- Standby generator systems

- Motor controls

- Power distribution labeling

- Specialty voltages (380 volt, 440y/254)

- Control panel builds and inspection

- Conveyor systems

Knowledge Base

Power Studies

Transformer Oil Analysis

Generators and Emergency Power Systems

Components of a Preventative Maintenance Plan

Replace worn components

before they fail

Clean and restore components before productivity is affected

Avoid consequences of

equipment failure

Improve equipment reliability

Train team on proper procedures

and techniques

Test equipment to identify faults

Where to Start When it Comes to Preventative Maintenance

Building out a preventative maintenance program can be daunting at first glance. We'll cover the basics to help you get started.

The Top 3 Reasons to Invest in Preventative Maintenance

Need proof of ROI when it comes to preventative maintenance? Look no further than these 3 reasons!

Use our Preventative Maintenance Checklist to Drive ROI

Preventative maintenance is an extremely familiar idea for any facility manager or plant manager. At its core,…

Read MoreHow preventative maintenance adds value on the plant floor

Are You Guilty of the “Band-Aid” Approach? The importance of checking ‘someday items’ off of your list…

Read MoreThe Top 5 Benefits of Preventative Maintenance

Ever heard of, “if it’s not broke, don’t fix it?” Unfortunately, this outdated train of thought still…

Read More